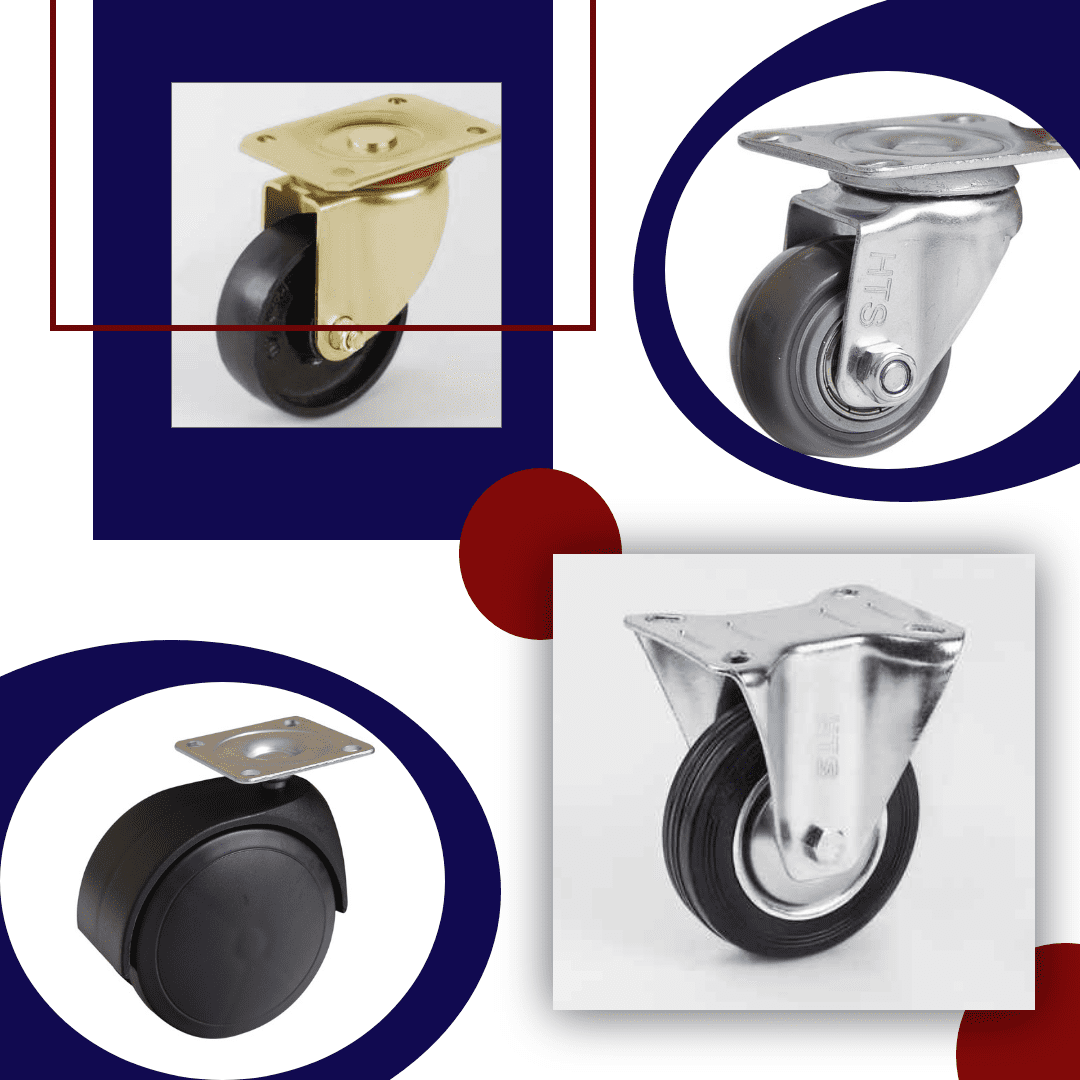

The best material for manufacturing Casters wheels

Choosing the right material is essential to ensure the performance, durability, and smooth operation of support wheels.

The materials used in the construction of supports influence load capacity, floor protection, noise reduction, and overall longevity. In this article, we will examine the characteristics of various types of materials used in the production of support wheels.

Rubber:

Rubber is a popular choice for support wheel construction due to its shock-absorbing properties and floor protection. Here are some advantages of rubber wheels for supports:

Rubber wheels reduce vibrations and noise during movement and are used in environments that require noise reduction. They prevent scratches or damage to the surface and also protect the floor.

Polyurethane:

Polyurethane is a versatile material with features such as smooth and quiet operation, high load capacity, stability, ease of movement, and floor protection. Polyurethane wheels for supports have high resistance to wear and impact.

Nylon:

Nylon wheels are known for their exceptional load capacity and are suitable for heavy-duty applications. Nylon wheels for supports provide long-term performance in challenging environments, resisting chemicals, oils, and solvents, making them ideal for industrial settings and laboratories.

Steel:

Normally, steel is used for frame construction and is also suitable for manufacturing support wheels for special applications since steel wheels can withstand high temperatures and are suitable for applications such as bakery ovens or industrial furnaces. They are also suitable for harsh environments with extreme conditions.

Iron:

Iron wheels for supports are known for their exceptional strength and durability. These materials are used in certain industrial applications, offering resistance to high temperatures, heat, and long lifespan.

Plastic:

Plastic wheels for supports are economical compared to other materials and lightweight, making them suitable where greater maneuverability is needed. Plastic wheels are corrosion-resistant and suitable for environments where exposure to moisture or chemicals is a concern. Additionally, plastic wheels are available in various colors and designs that complement any environment. Compared to other support wheels, plastic wheels are an excellent choice for light or medium-duty applications.

Choosing the Right Materials:

When selecting the best material for wheels, the following factors should be considered:

- Load Capacity: Evaluate the required weight and choose materials capable of handling the expected load.

- Floor Surface: Consider the type of flooring in your environment and choose materials that provide adequate floor protection without causing damage.

- Noise Reduction: If noise reduction is crucial, choose materials such as rubber or polyurethane with quiet operation.

- Durability: Assess the durability needs of your application and select materials that can withstand the anticipated conditions and frequency of use.

Latest Developments

Explore to stay up to date with us.