HTS TEKER olarak

Yükünüzü Hafifletiyoruz!

40 Yıldır Türkiye’nin Mobilya Tekerlek Markası

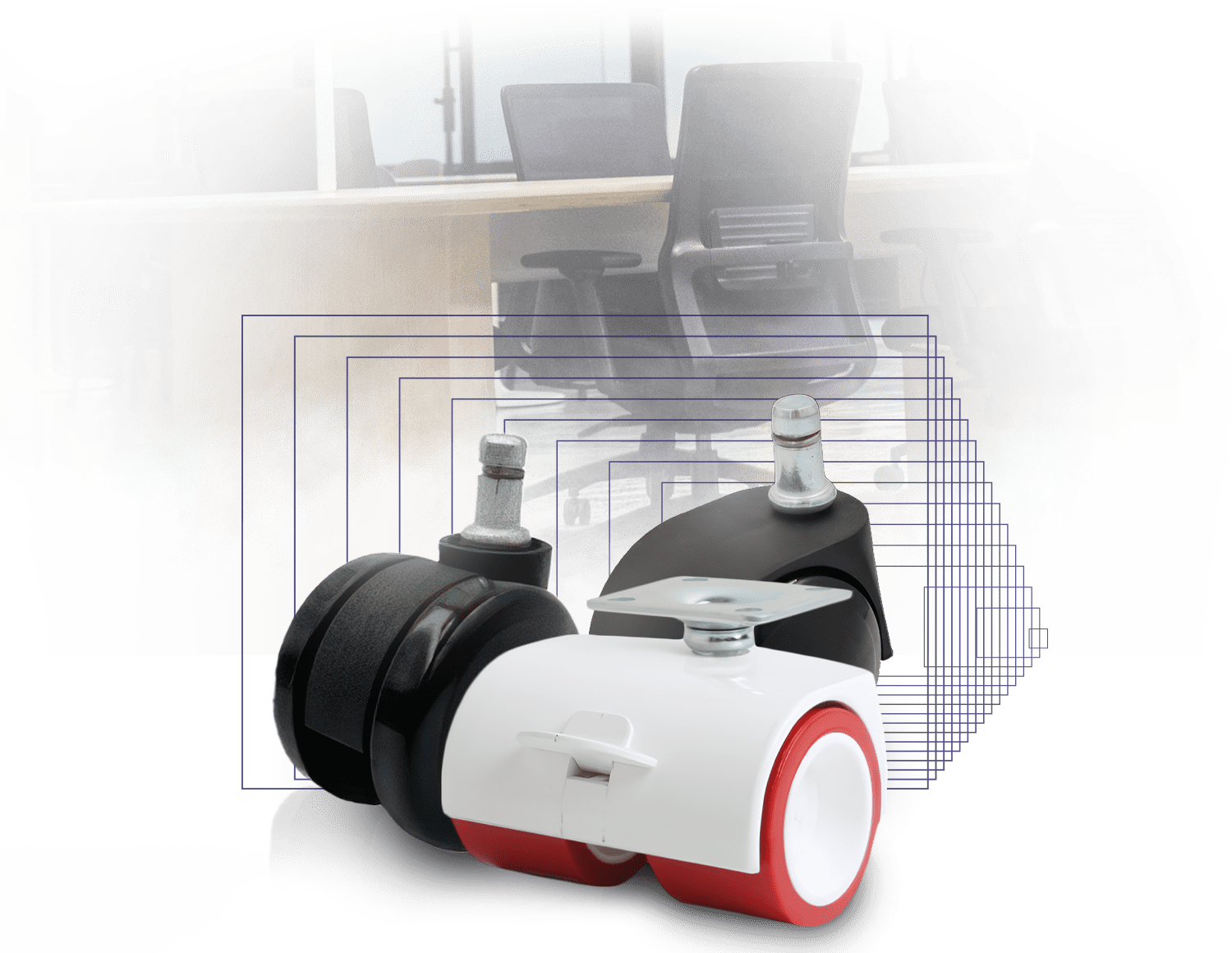

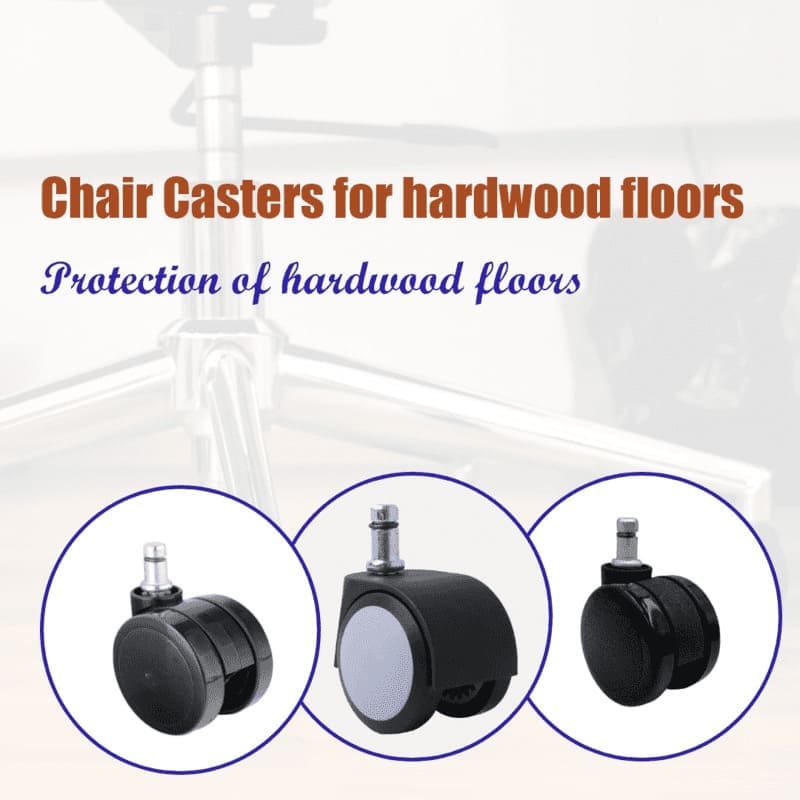

HTS Teker, Türkiye’nin önde gelen tekerlek üreticisi olarak mobilyadan ağır sanayiye kadar geniş bir yelpazede profesyonel hizmet sunmaktadır. Kaliteli üretim ve geniş ürün çeşitliliğiyle fark yaratıyoruz. Ofis koltukları ve mobilyalarının yanı sıra, frenli veya frensiz, yüksek taşıma kapasiteli, ekonomik veya dekoratif tekerlekler de sunmaktayız. Müşterilerimizin çeşitli ihtiyaçlarına ve tercihlerine hitap ettiğimiz kapsamlı ürün yelpazemizle öne çıkıyoruz.

bizimle her zaman kolayca iletişime geçebilirsiniz!

KURUMSAL

Bize Ulaşın

Hareketli Çözümler ile Tanışın!

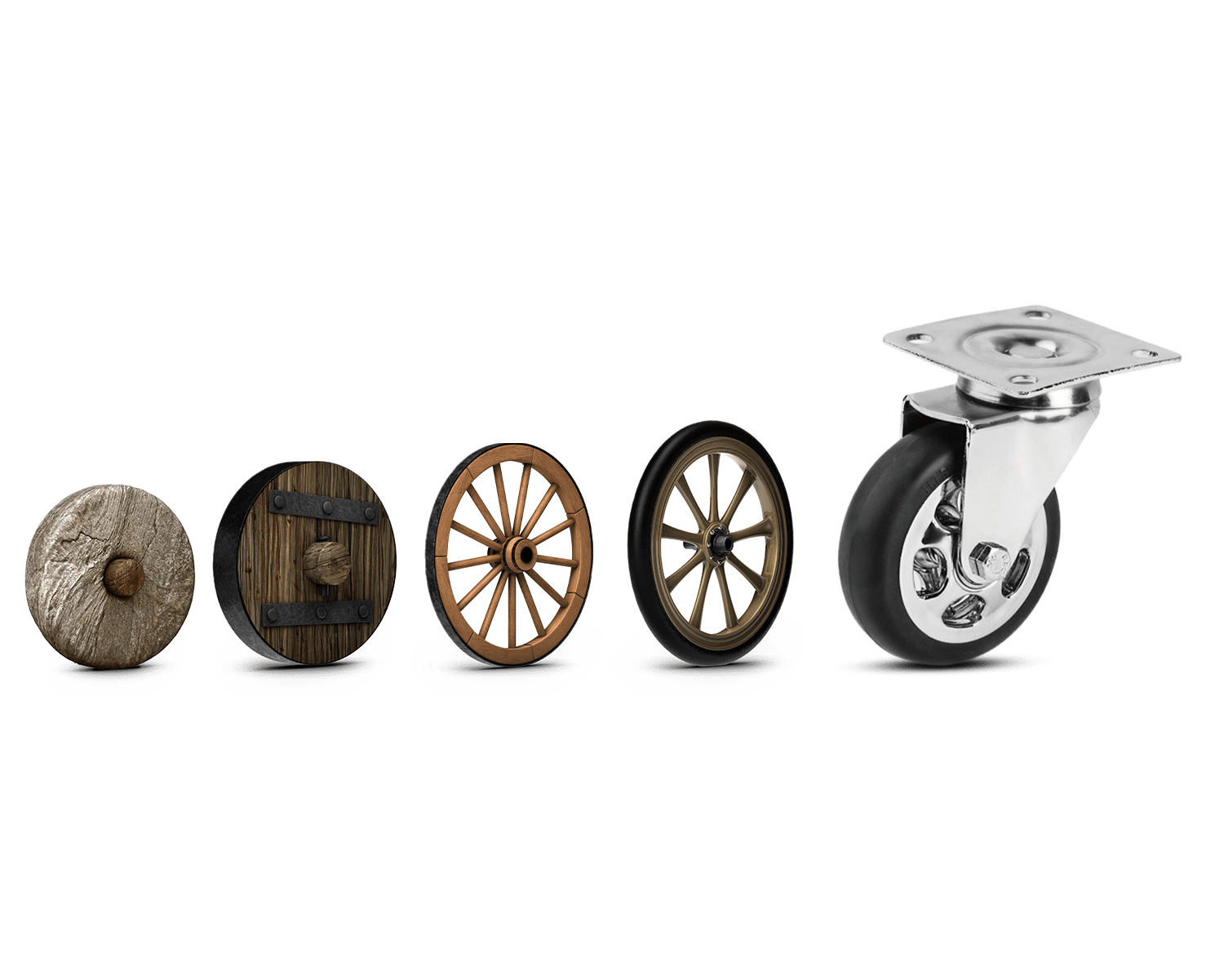

Dünyadaki ilk icat olan tekerlek üretiminde 40 yıllık bilgi birikimi ve 58 yıllık sanayici tecrübesiyle, HTS Teker teknolojinin çağdaş alt yapısını kullanarak müşteri memnuniyetini temel ölçüt olarak kabul etmiştir.

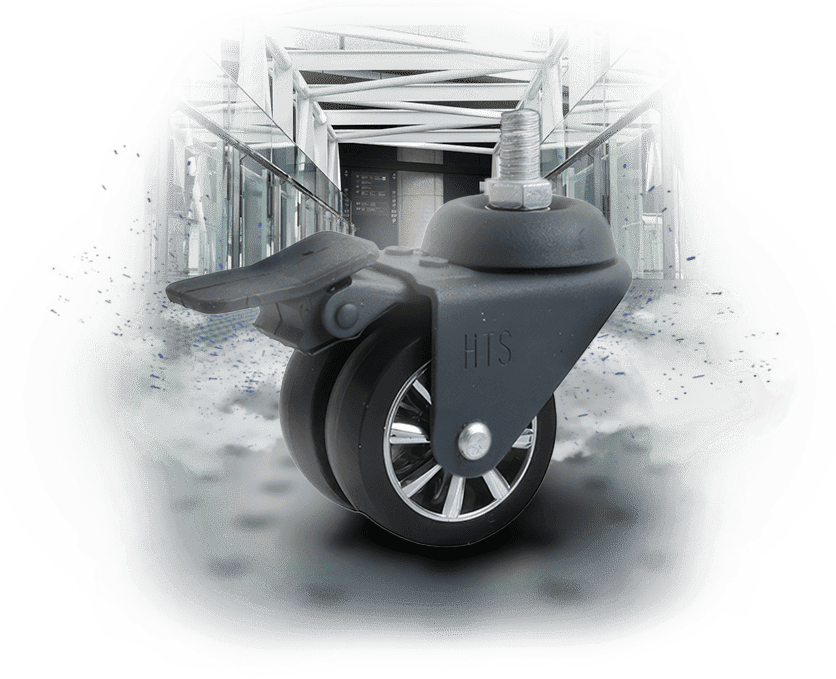

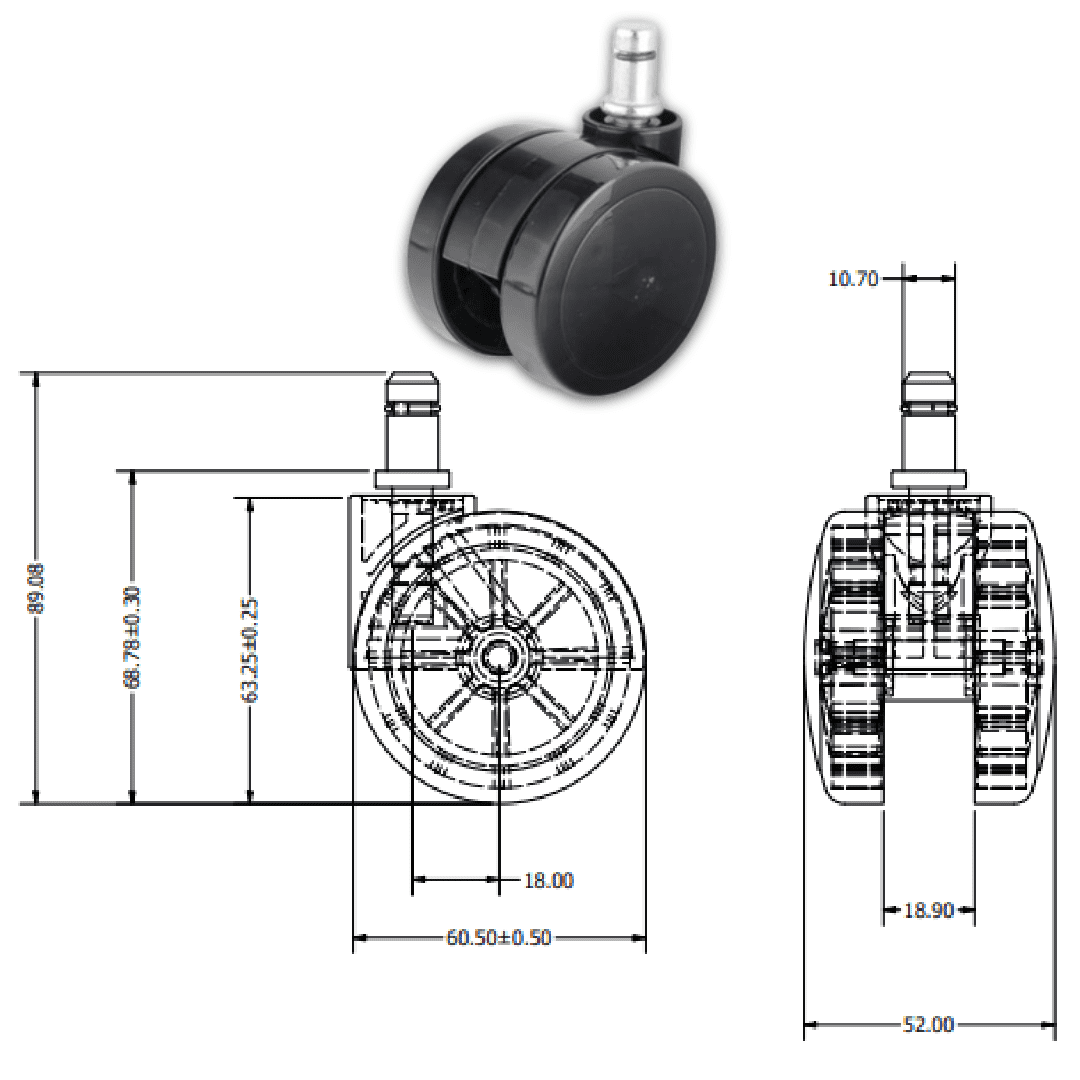

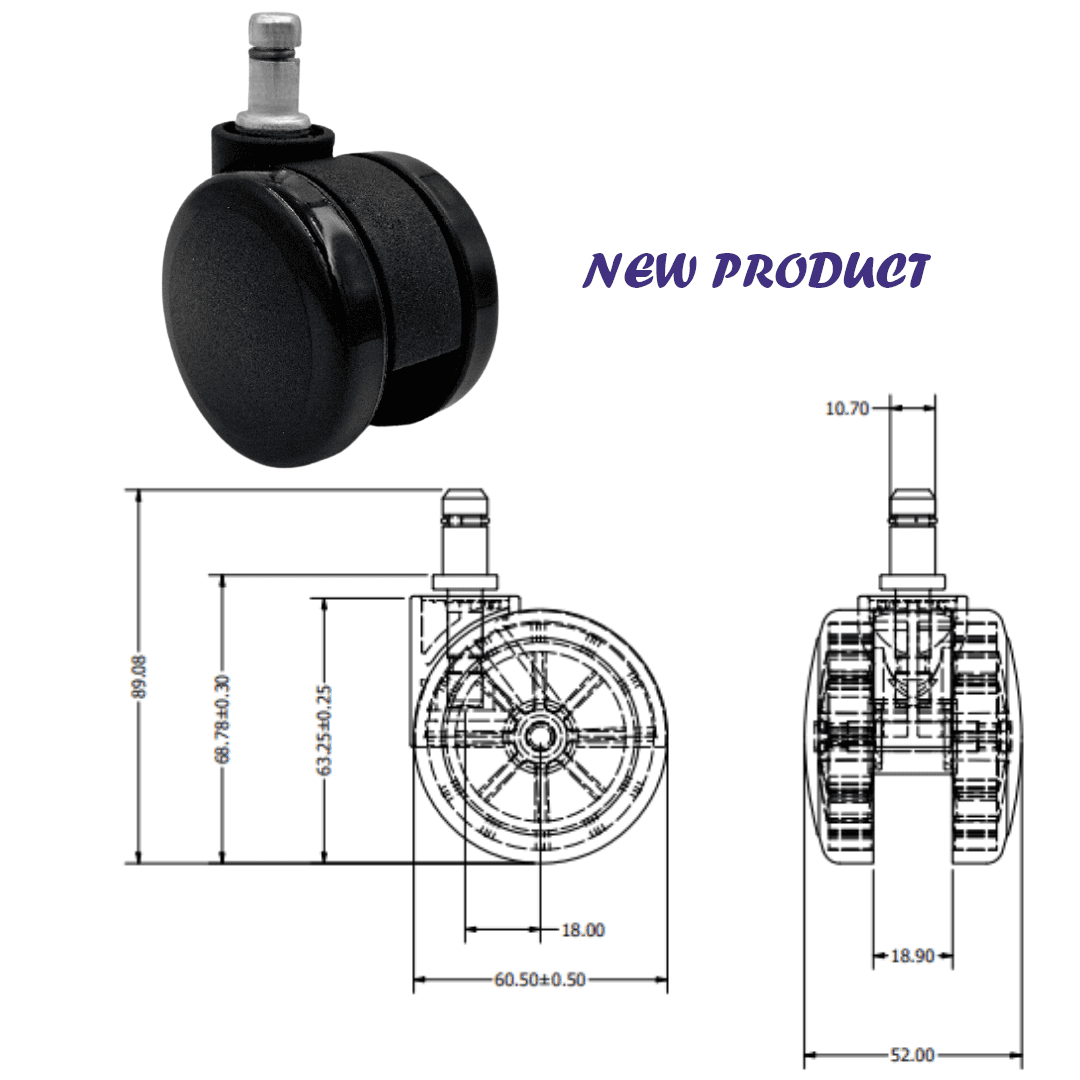

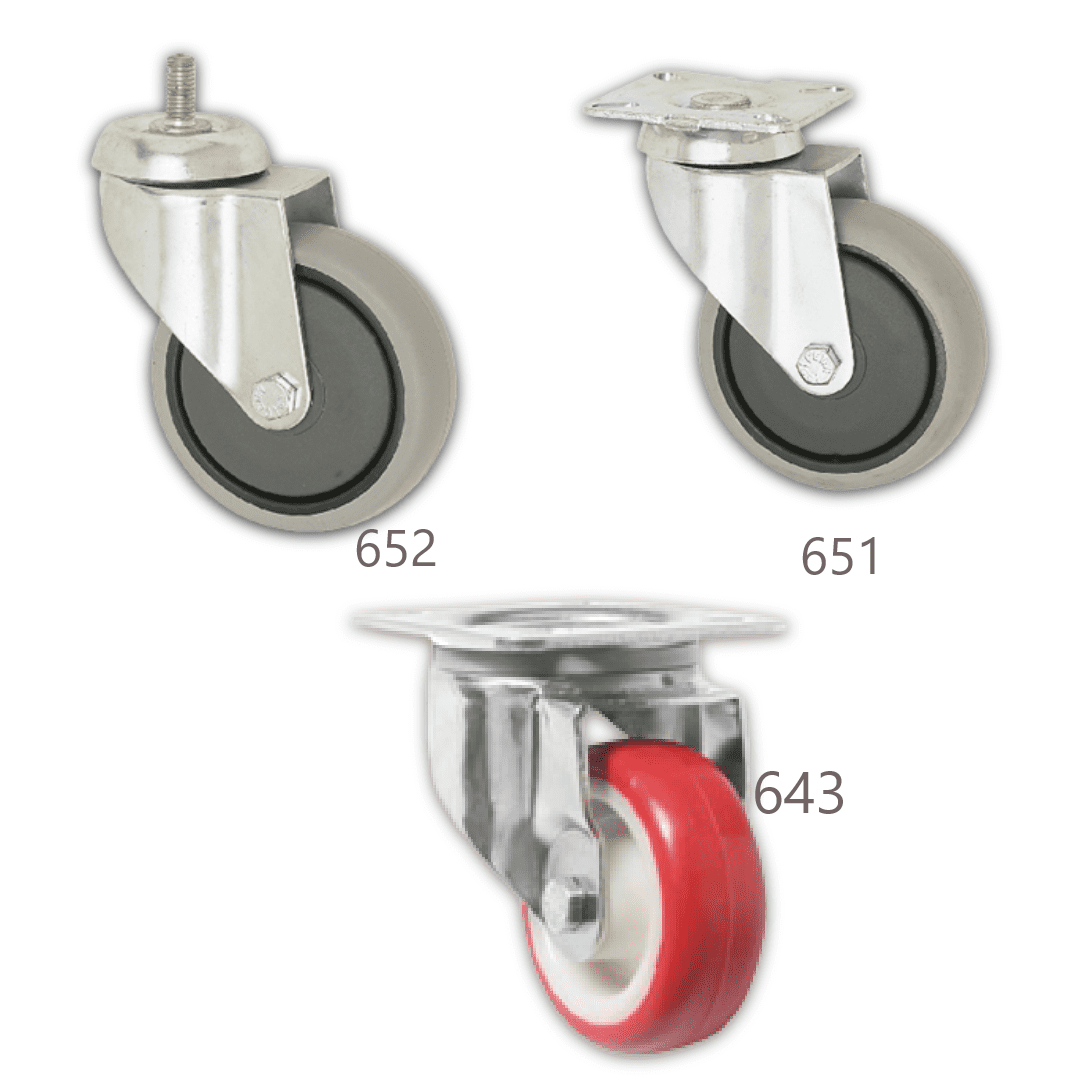

Metal ve plastik olan ikiye ayrılan bu ürünün başlıca özellikleri frenli ve frensiz, dönerli ve sabit olarak kullanıcı dostu olmasıdır. Ek olarak, ekonomik, dekoratif ve işlevsel olarak da dikkat çekici modeller bulunmaktadır. Projenize ve tercihinize göre ürün tavsiyesi almak için bize ulaşın!

AVRUPA’NIN EN GENİŞ ÜRÜN ÇEŞİDİNİ ÜRETEN MARKASI

Geniş ürün çeşitliliği sayesinde birçok farklı müşteri profiline uygun çözümler üretebilen HTS Teker, kaliteli ve yüksek kapasiteli üretimi ile 40 yıldır hizmet sunmaktadır. Yurtiçi ve yurtdışı müşterilerimizin talepleri, öneri ve görüşleri ışığında tekerleği daha iyi döndürmek için çalışıyoruz.

Son Gelişmeler

Bizden daha fazla haberdar olmak için keşfedin.